CONTACT INFO

JINAN FAST CNC MACHINERY CO., LTD

WhatsApp:086-15098878331

Mobile: 086-15098878331

E-mail: chelsea@fastechcnc.com

lfqft@163.com

Fax:086-0531-87459135

Add: No 8521 WEST JIGSHI ROAD, JINAN.CHINA

Zip:250300

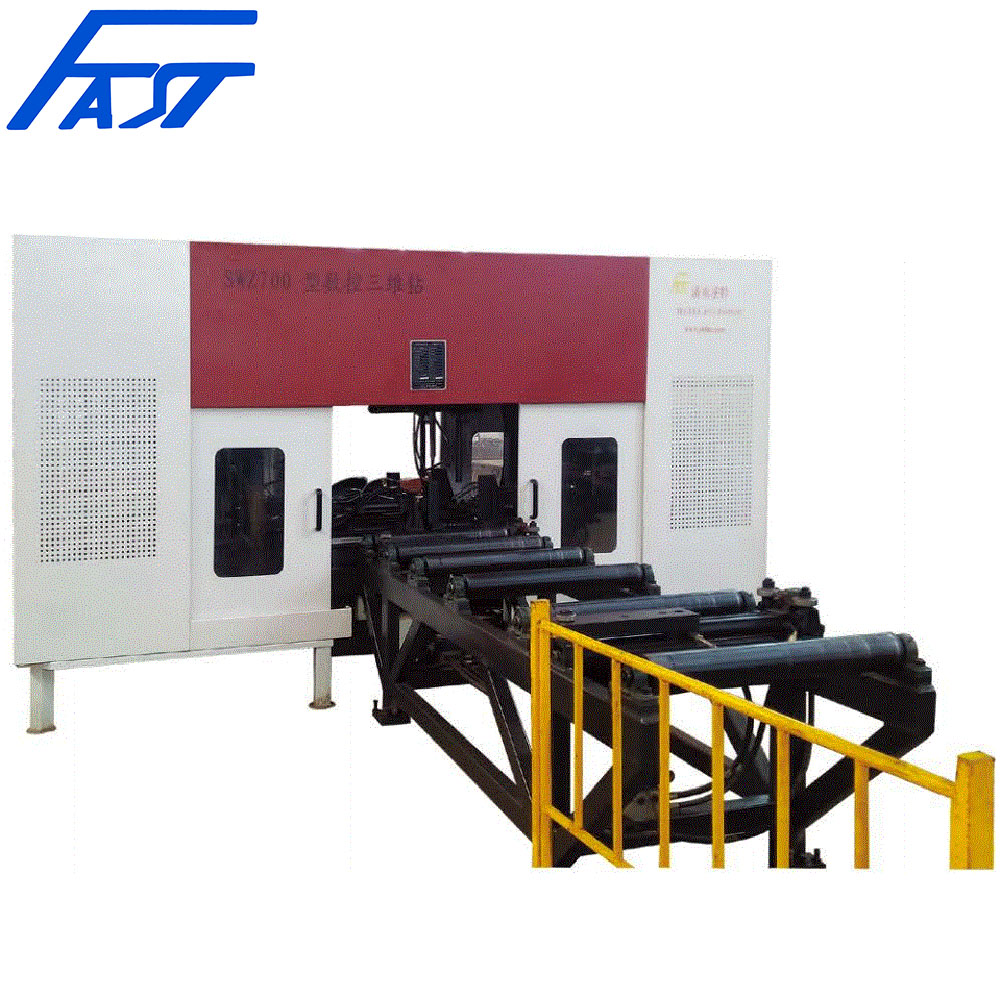

Nine-Spindle CNC Beam Drilling Machine

APPLICATION

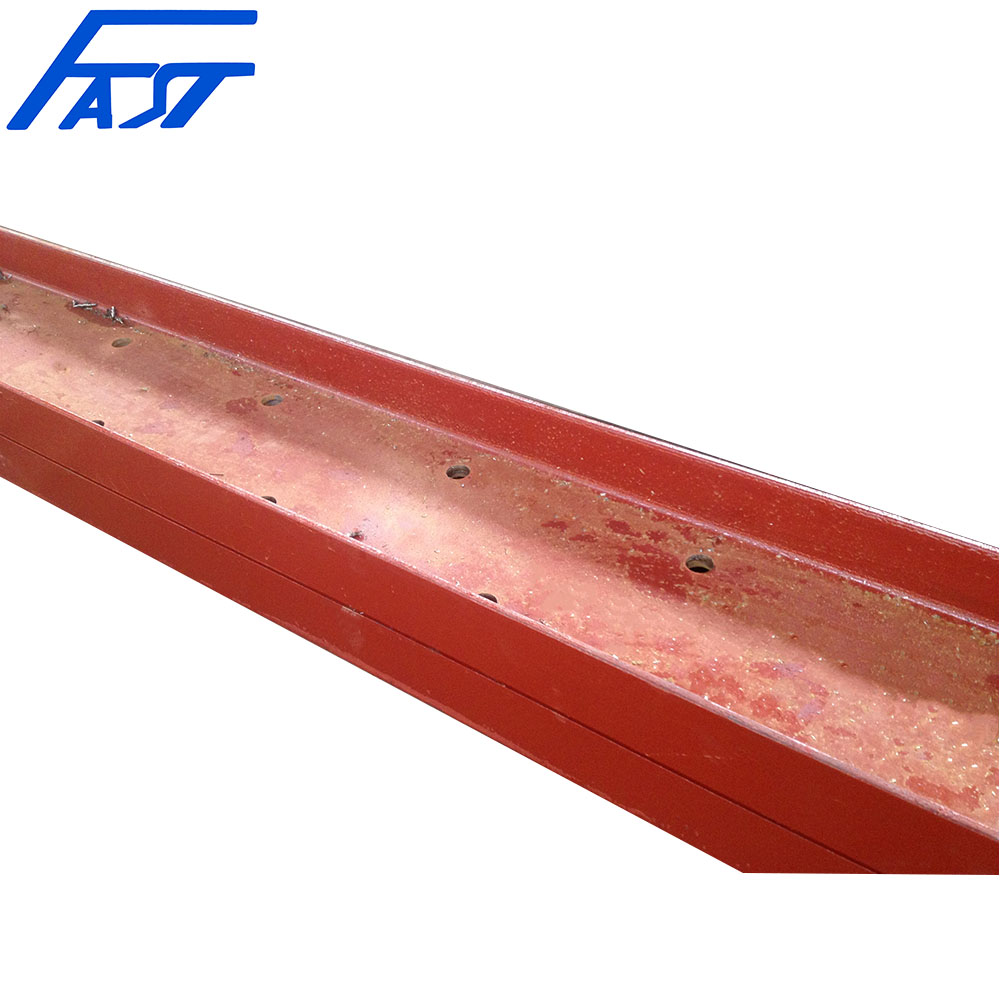

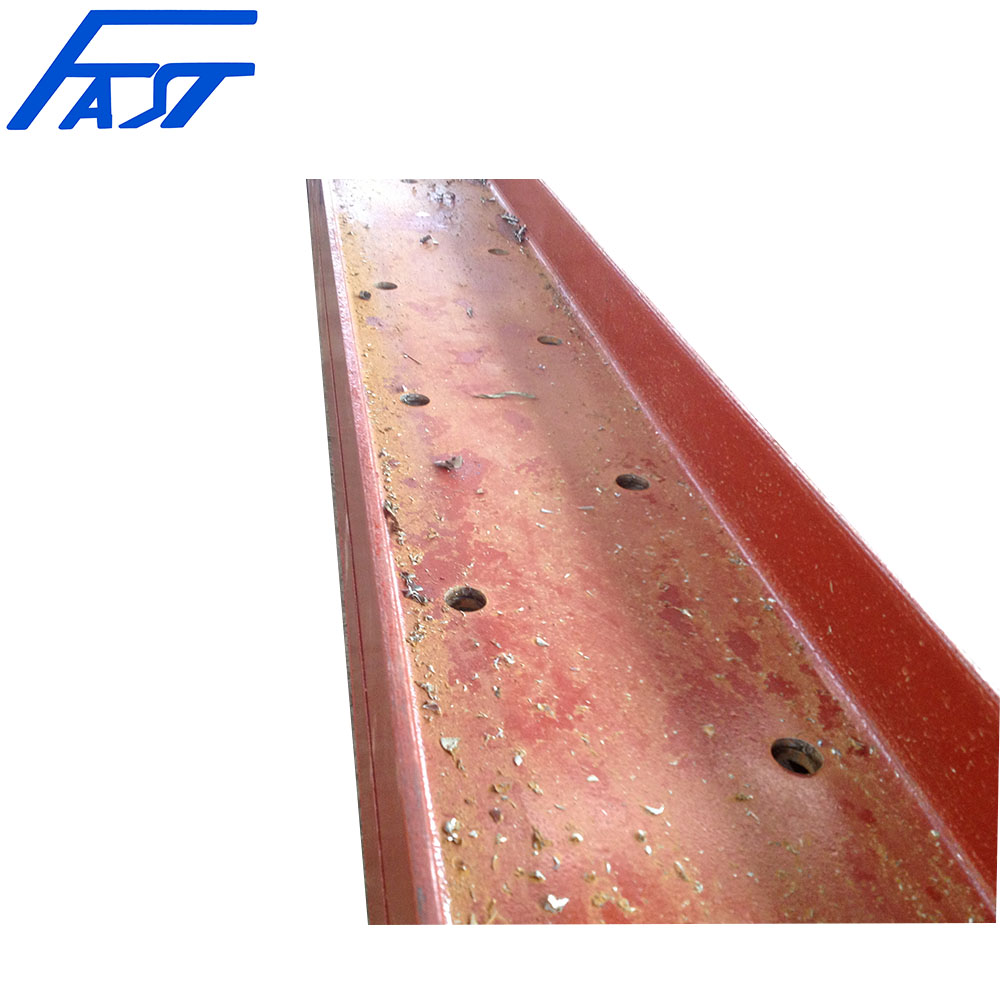

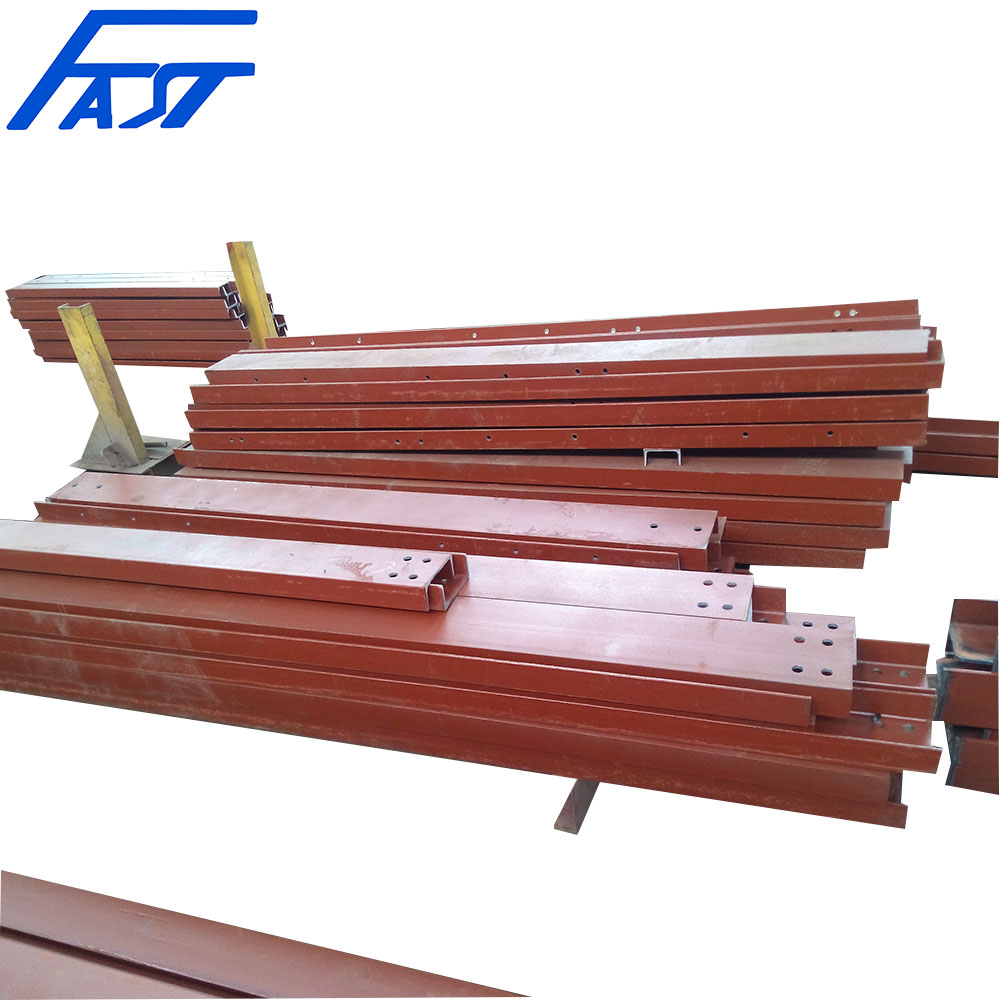

This machine is used for the drilling processing of H-shape steel, box beam and channel steel of steel structure, bridge, three dimensional garage and petrol platform.

ADVANTAGES

● There are 9 independent drilling spindles, 3 vertical and 6 horizontal (right and left).

● 9 drilling heads can drill holes simultaneously. Also, the drilling head is self-controlled stroke.

● As long as inputting dimensions of workpiece, the processing program can be memorized, selected, displayed and transmitted according to wokpiece at will.

● CNC and PLC systems, CRT displaying. Programming Microsoft is based on Windows. Programming Microsoft can be in any computer to run programing off-site. It directly by copy/internet transfer to equipment.

● The feeding of the workpiec is driven by rollers, which are controlled by hydraulic and mechanical systems. The measuring wheel measures the actual feeding distance of workpiece and feeds back the result to control system to guarantee the precision the longitude position of holes.

● Drilling heads are equipped with main shaft reducer.

TECHNICAL DATA

ITEMS

UNIT

SPECIFICATIONS

H Beam: Max width * Max Height

mm

700×400

H Beam: Min width * Min Height

mm

100×50

Automatic Feeding Length

mm

8000

Max Web Thickness

mm

≤40

Max Weight

kg

4000

Quantity of Drilling Spindle

PCS

9

Power of Drilling Spindle

r/min

100~560

Rotation Range of Each Spindle

mm/min

20~200

Feeding Speed

mm

220

Feeding Stroke of Upper Spindle

mm

220

Feeding Stroke of Lfet Spindle(Reference)

mm

Φ6-φ40

Feeding Stroke of Lfet Spindle

Mm

Center Line Moving Range

Upper Spindle Transverse(left and right) movement range

mm

30~660

Left and Right Spindle Vertical (up and down) movement range

mm

30~360

Non-reference Side Level Range of Movement

mm

400

Clamp Type

Morse

4#

Hole Tolerance Within the Hole Group

mm

±0.5

Hole Tolerance Between the Hole Group

mm

±0.75

Pressure of Compressed Air

MPa

0.4-0.6

Cooling

Air Cooling

Clamp Up & Down (Vertical direction) Stroke

mm

220

Clamp Movement ( Forward direction) Stroke

mm

9500

Servo Motor Power of Power Rack & Pinion Drive

KW

Appro.4

Outline Dimension of feeding Channel(L*W*H)

mm

9500×1250×1630

Length of Discharging Channel

mm

8000

Total Power

KW

Appro.30

L×W×H Outline Dimension of the line

mm

20000×4220×3120

CAD Automatically change to controlling system

FAQ

· Are you a Manufacturer or a Trading company?

Manufacturer + trading company (integration),focusing on CNC machines for 18 years. Integration with Design,Machining and Assembly.

Exporting to Russia,USA,Australia,Vietnam,Brazil,Ethiopia,Tunisia,Bulgaria,India,Indonesia,Jordan,Pakistan,etc

· Do you have stock product ready to delivery?

In order to satisfy with customer for fast delivery, we have certain amount of machines in stock.

· After an order is placed,when to delivery?

General 30 working days. It depends on specific items and item quantities.

Please check with sale manager for exact delivery time.

· What is the Warranty with After-sale Services?

12 months warranty after delivery. Engineers will provide training program for operation and trouble shouting during installation. They visit customers regularly for service. All questions will be answered within 3 hours and 90% problem will be solved within 24 hours.

After the warranty, the professional after-sale service team will provide perfect technical support and help customer solve problems encountered.

· What about the product quality?

Each machine must be carried out quality examination and test when shipping and delivery goods.