CONTACT INFO

JINAN FAST CNC MACHINERY CO., LTD

WhatsApp:086-15098878331

Mobile: 086-15098878331

E-mail: chelsea@fastechcnc.com

lfqft@163.com

Fax:086-0531-87459135

Add: No 8521 WEST JIGSHI ROAD, JINAN.CHINA

Zip:250300

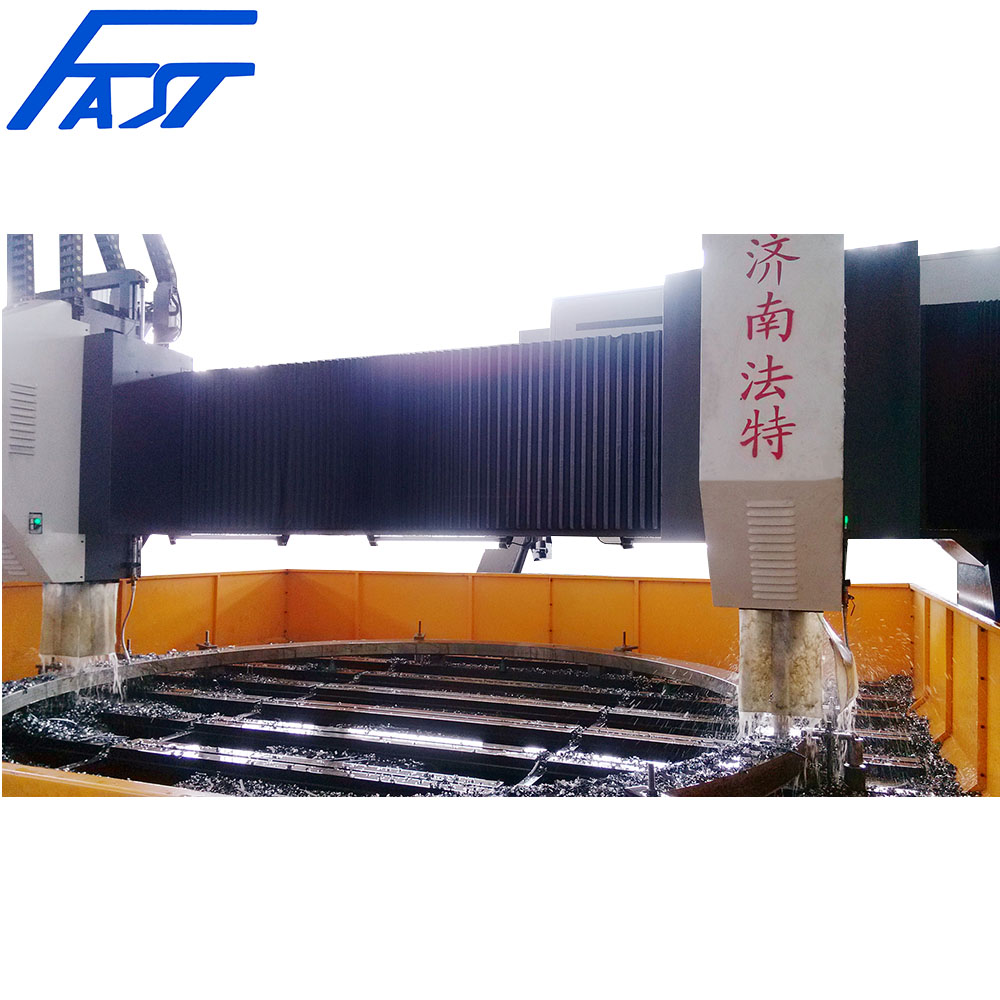

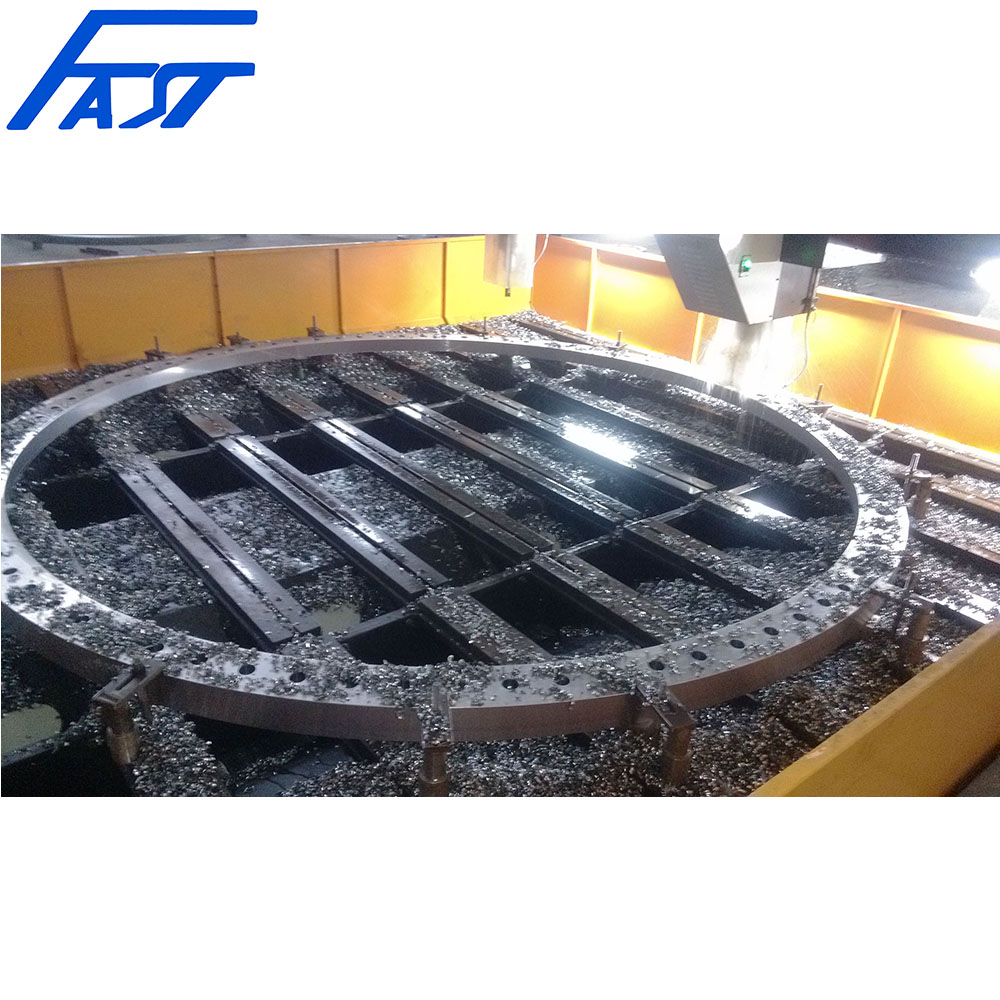

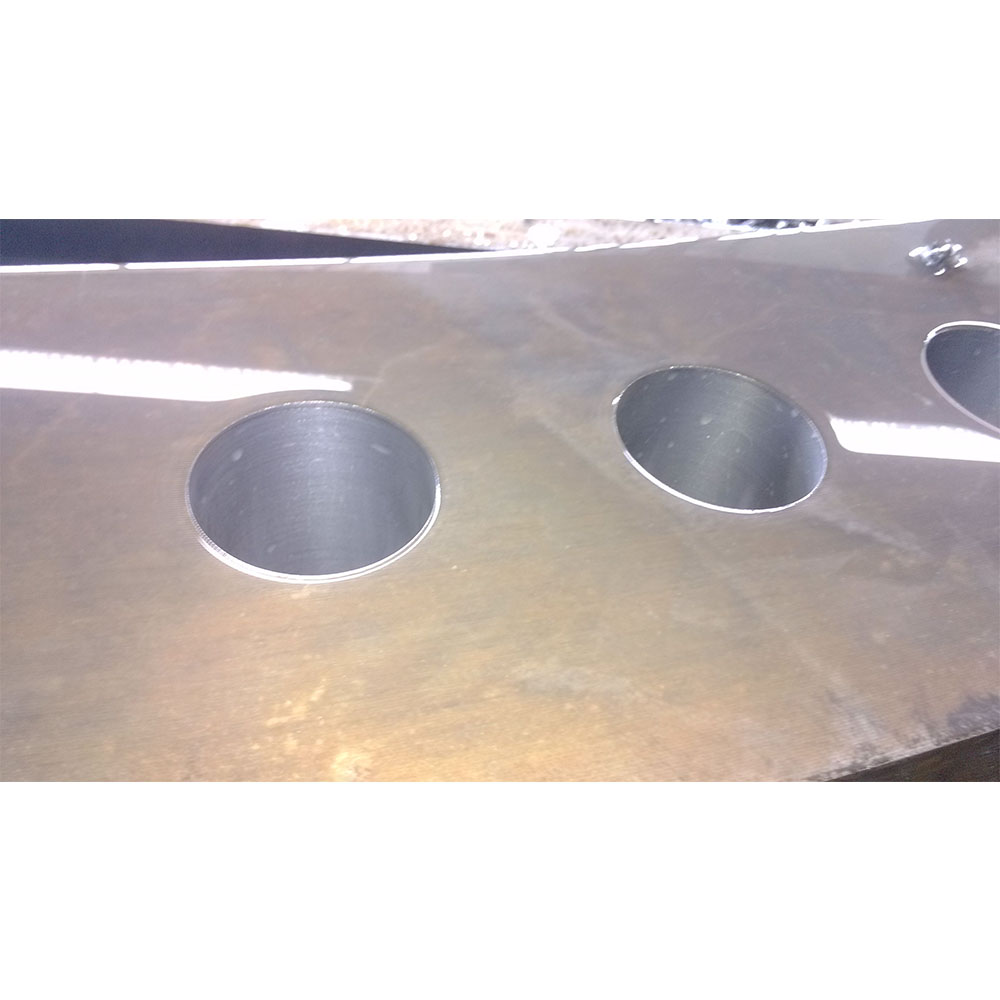

Double Spindle High Speed Flange Tubesheet Drilling Machine PZG5050

APPLICATION

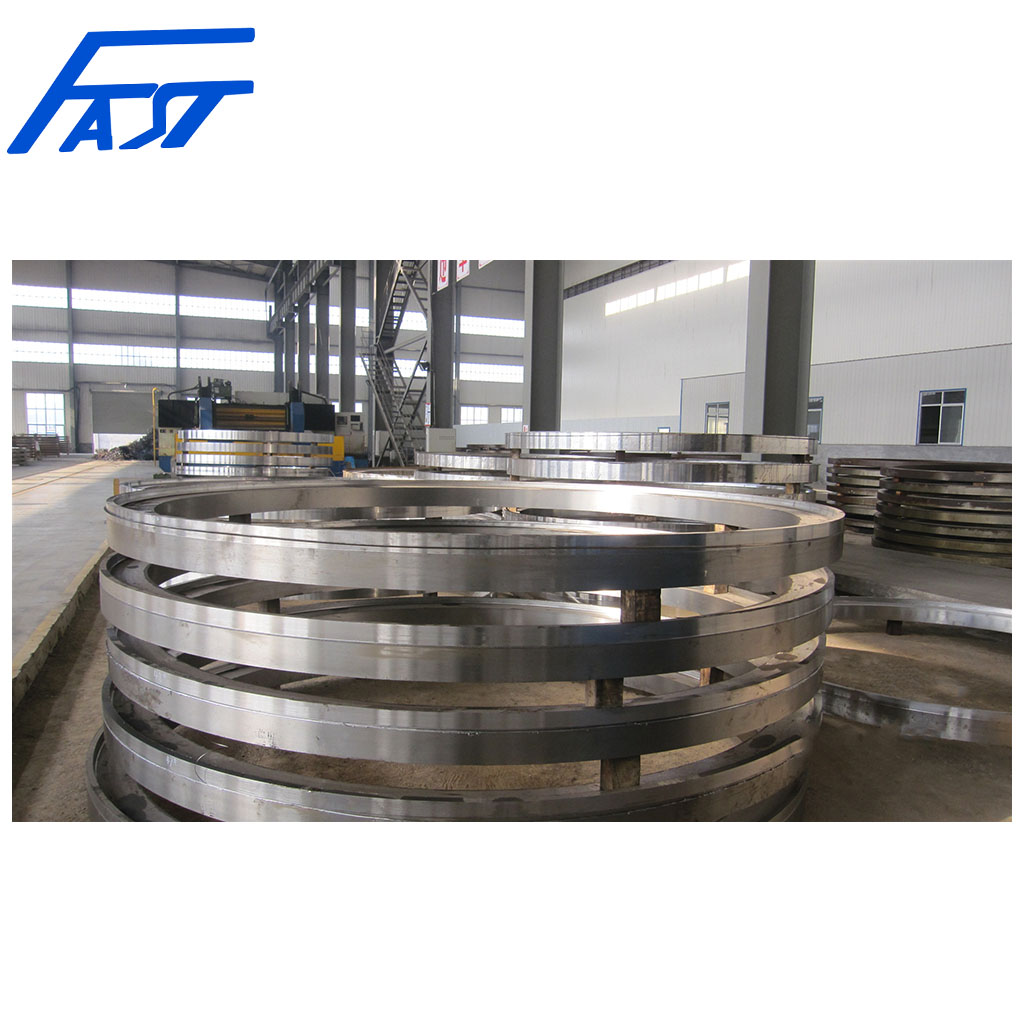

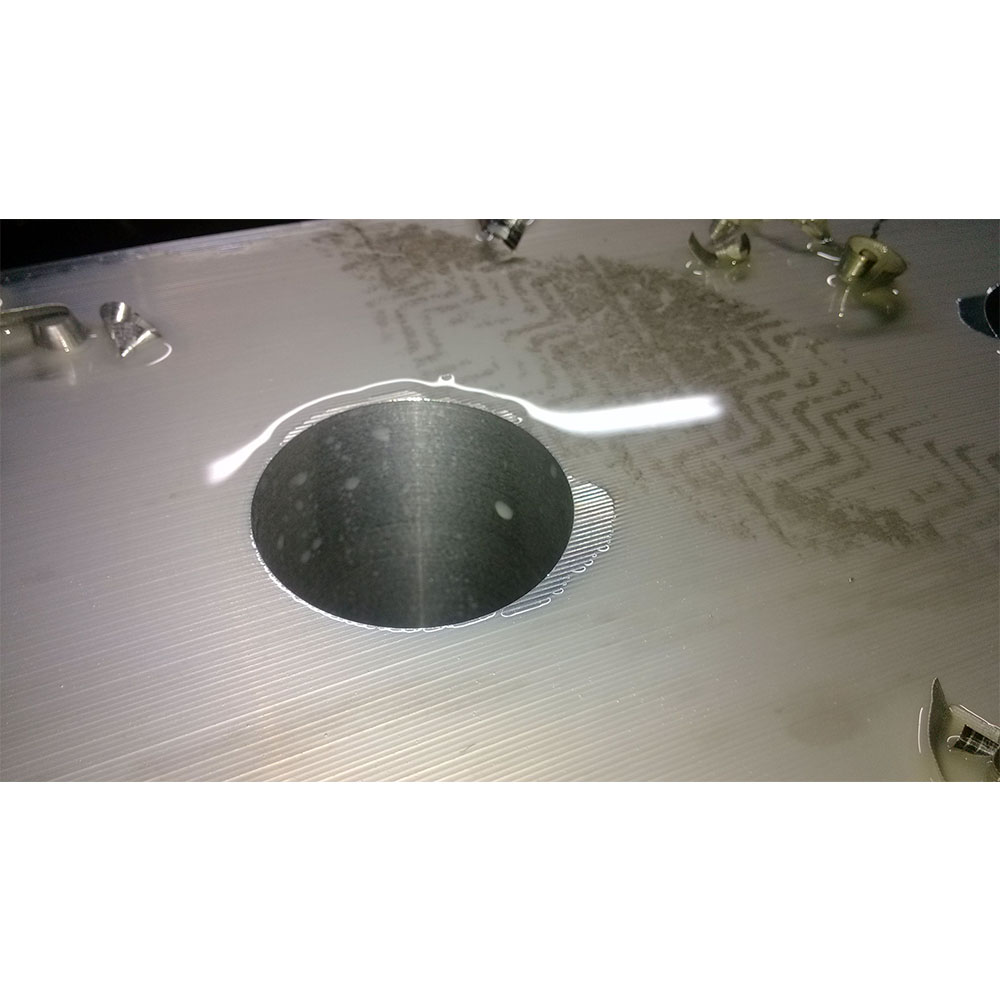

This machine is used for the drilling,tapping and milling for tube plate, clapboard,flange and rings. It is used in petrochemical, boiler, and wind power flange industries, also for joint plates in building, bridge, iron tower, etc. It is suitable for carbon steel or composite materials. Carbide milling cutter or high speed steel twist drill bit are adopted. Digital control can realize automation, high precision, varieties, batch production.

COMPOSITION

Left and right gantry base

Worktable

Longitudinal movablegantry

Transverse movable saddle

Vertical sliding pillow drilling power head

Automatic chip removal

Circulating cooling unit

Hydraulic system

TECHNICAL DATA

Model

PZ2020G

PZ3030G

PZ4040G

PZ5050G

PZ6060G

Max. Size of Work piece(mm)

Max.Hole Distance L×W (mm)

2000*2000

3000*3000

4000*4000

5000*5000

6000*6000

Max. Thickness (mm)

250

250

250

250

250

The Distance Between The Lower Part of The Axes and the Work

Bench(mm)

230~730

Milling

Φ100 Cutter Head, Depth 2mm (Material Q345)

Max. Drilling Diameter (mm)

Φ50

Φ50

Φ50

Φ50

Φ60

Drilling power head Quantity

1

1 OR 2

2

2

2

Main Axes Taper Hole

BT50

Rotating Speed of Drilling Spindle (r/min)

30~2500

30~2500

30~2500

30~2500

30~2500

Motor Power of Drilling Spindle (kW)

22

22

OR 22*222*2

22*2

22*2

Longitudinal Movement(X-axis) Max Stroke (mm)

2000

3000

4000

5000

6000

X-axis Movement Speed (m/min)

0~8000

Lateral Movement(Y axis) Max. Distance (mm)

2000

3000

4000

5000

6000

Y-axis Movement Speed (m/min)

0~8000

Vertical Max. Stroke of Z-axis

500

500

500

500

500

Feeding Speed of Z axis

0~4000

Positioning accuracy

≤0.04

Repeat positioning accuracy

≤0.03

Number of clip cleaner

2

Speed of Clip Removal (m/min)

1

Clip Removal Motor Power(kW)

20.75

Outline Dimension L*W*H(mm)

4600*4200*3900

5800*5520*3900

7600*6540*3900

9200*8500*4300

9680*9520*6000

Machine Weight(T)

24

35

56

70

75

★ All of these models can be customized according to customer requirements.

FAQ

· Are you a Manufacturer or a Trading company?

Manufacturer + trading company (integration),focusing on CNC machines for 18 years. Integration with Design,Machining and Assembly.

Exporting to Russia,USA,Australia,Vietnam,Brazil,Ethiopia,Tunisia,Bulgaria,India,Indonesia,Jordan,Pakistan,etc

· Do you have stock product ready to delivery?

In order to satisfy with customer for fast delivery, we have certain amount of machines in stock.

· After an order is placed,when to delivery?

General 30 working days. It depends on specific items and item quantities.

Please check with sale manager for exact delivery time.

· What is the Warranty with After-sale Services?

12 months warranty after delivery. Engineers will provide training program for operation and trouble shouting during installation. They visit customers regularly for service. All questions will be answered within 3 hours and 90% problem will be solved within 24 hours.

After the warranty, the professional after-sale service team will provide perfect technical support and help customer solve problems encountered.

· What about the product quality?

Each machine must be carried out quality examination and test when shipping and delivery goods.