CONTACT INFO

JINAN FAST CNC MACHINERY CO., LTD

WhatsApp:086-15098878331

Mobile: 086-15098878331

E-mail: chelsea@fastechcnc.com

lfqft@163.com

Fax:086-0531-87459135

Add: No 8521 WEST JIGSHI ROAD, JINAN.CHINA

Zip:250300

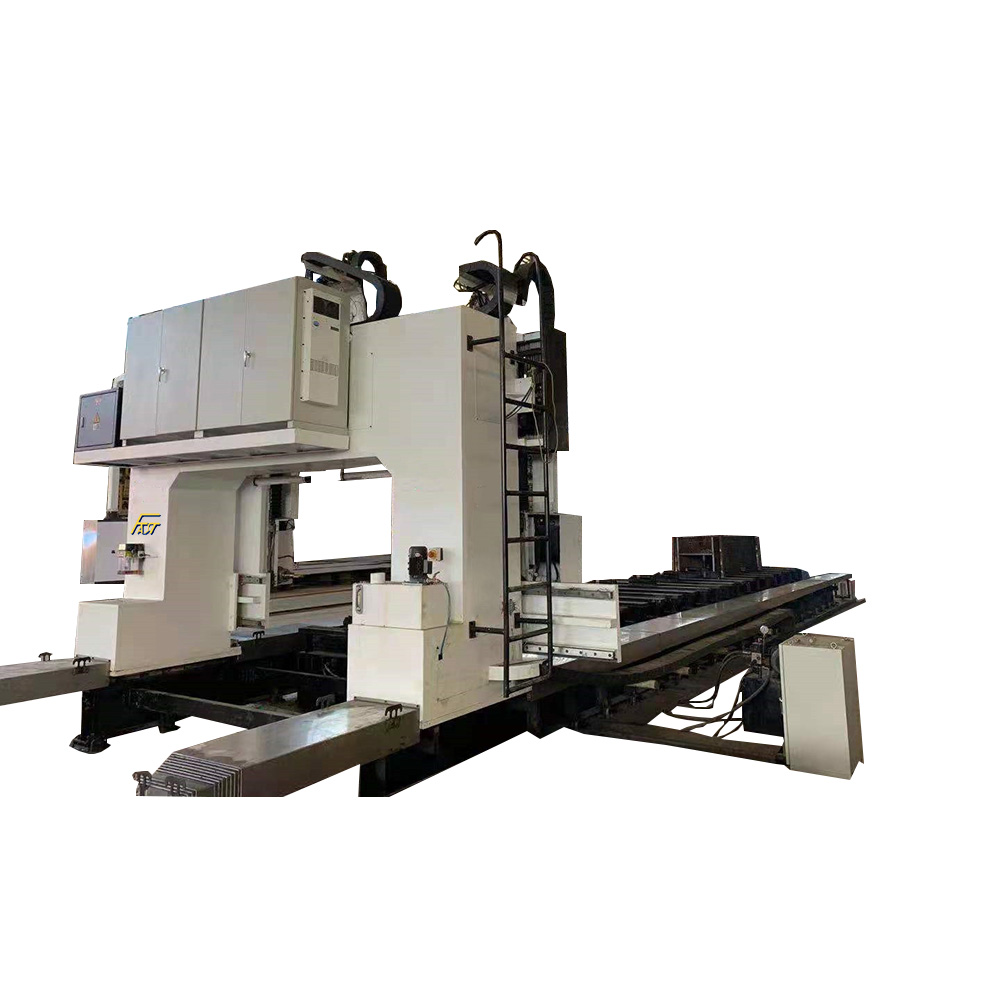

SDM360 x 200 x 10000 Gantry Movable CNC Drilling &Milling Machine | H-beam Drilling Milling Process Line

Category:STEEL STRUCTURE/STEREO GARAGE

Product specifications:

Beam drill line, Gantry movable CNC drilling &milling machine,H-beam drilling milling process line, Structural steel beam drill line

SDM360 x 200 x 10000 Gantry Movable CNC Drilling &Milling Machine

APPLICATION

This machine is mainly used for drilling and milling of groove beam, H-beam and other structural parts. Three sides can be processed simultaneously, and one side can be processed.

If requested, tapping can be added and a knife library is also available.

MODEL EXPLAINATION

SDM---Section Steel Drilling and Milling

360: Width of section steel is 360mm

200:Height of section steel is 200mm

10000: Section steel length 10000mm

TECHNICAL DATA

SPECIFICATION

UNIT

PARAMETERS

Worktable

Effective table size

mm

360×10000

Can pass workpiece width

mm

560

Load capacity

t

10

Upper power head unit

Spindle specification

BT40 precision high speed spindle

Tool cooling mode

Central spray internal cooling + gas-liquid external cooling

Loosing tool method

Pneumatic loosing tool

Spindle servo motor power

kW

15

Range of spindle speed

r/min

0-3000

Left and right power head units

Spindle specification

BT40 precision high speed spindle

Tool cooling mode

BT40 precision high speed spindle

Loosing tool method

Pneumatic loosing tool

Spindle servo motor power

kW

15

Range of spindle speed

r/min

0-3000

Processing capability

Drilling

mm

φ30 Carbide drill

mm

φ40 twist drill

Milling

mm

φ30 milling tool

Tapping

M20(Optional Item)

Automatic tool changer

3 tool manazine, each magazine has 4 tools (optional)

CNC axes number and servo motor

CNC Axes

8 axes(Withour tool hoder)

12 axes

(With auto tool holder)

Spindle servo motor power

kW

15×3

The spindle feeds the servo motor power

kW

2KW×3

(With precision reducer)

Gantry and power head move servo motor power

kW

2KW×5

(With precision reducer)

Tool magazion servo motor power

kW

0.6KW

One rotary tool magazine is used, 2 inline tool magazine are not used

Controlling system

Controlling system

Computer+PLC

(Without Tapping)

tandard CNC system

(with tapping)

Cooling system

Cooling method

(See power head unit description)

Air source pressure (supplied by user)

mPa

0.6

Chip removal system

Power of a screw chip drainer

kW

1.1(Optional Item)

Machine total power

kW

about 53

Total weight

T

about 15

Outline demension

L*W*H

mm

About 11000×2000×3000

FAQ

· Are you a Manufacturer or a Trading company?

Manufacturer + trading company (integration),focusing on CNC machines for 18 years. Integration with Design,Machining and Assembly.

Exporting to Russia,USA,Australia,Vietnam,Brazil,Ethiopia,Tunisia,Bulgaria,India,Indonesia,Jordan,Pakistan,etc

· Do you have stock product ready to delivery?

In order to satisfy with customer for fast delivery, we have certain amount of machines in stock.

· After an order is placed,when to delivery?

General 30 working days. It depends on specific items and item quantities.

Please check with sale manager for exact delivery time.

· What is the Warranty with After-sale Services?

12 months warranty after delivery. Engineers will provide training program for operation and trouble shouting during installation. They visit customers regularly for service. All questions will be answered within 3 hours and 90% problem will be solved within 24 hours.

After the warranty, the professional after-sale service team will provide perfect technical support and help customer solve problems encountered.

· What about the product quality?

Each machine must be carried out quality examination and test when shipping and delivery goods.