CONTACT INFO

JINAN FAST CNC MACHINERY CO., LTD

WhatsApp:086-15098878331

Mobile: 086-15098878331

E-mail: chelsea@fastechcnc.com

lfqft@163.com

Fax:086-0531-87459135

Add: No 8521 WEST JIGSHI ROAD, JINAN.CHINA

Zip:250300

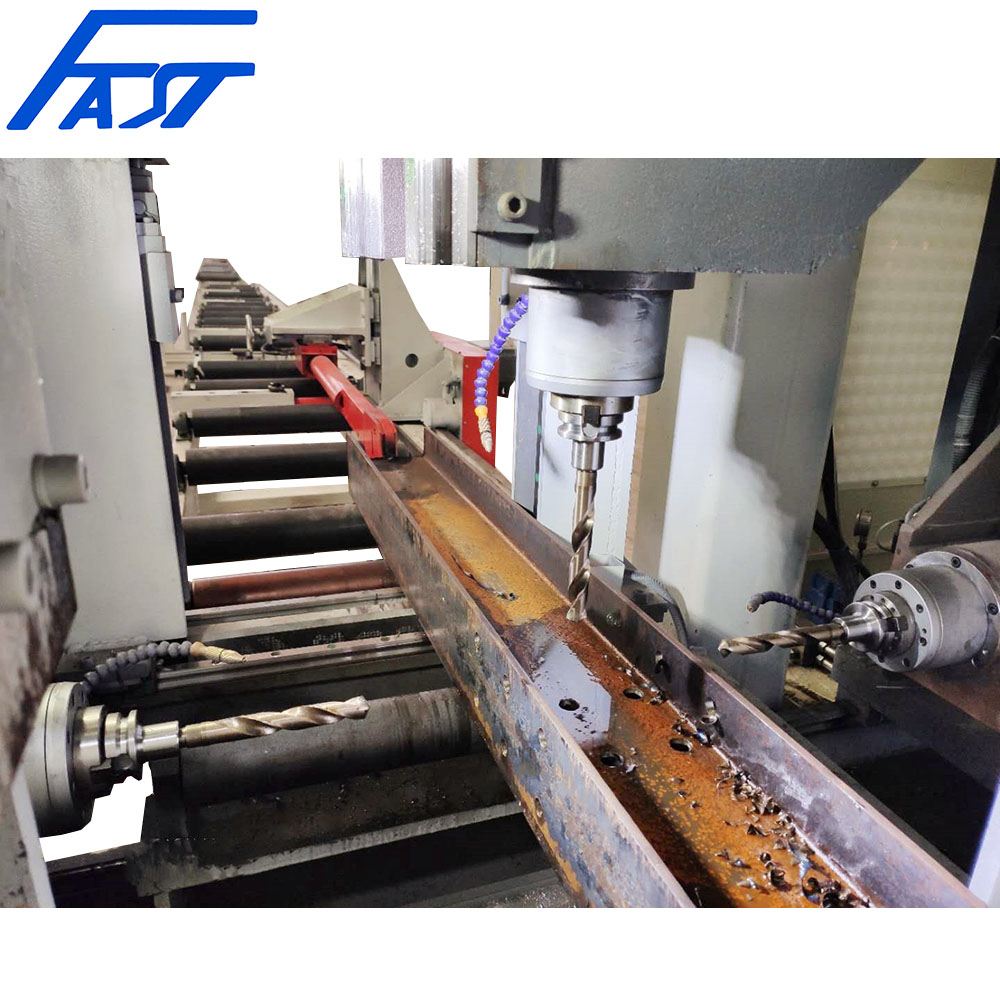

Jinan FAST High-Speed CNC H Beams Drilling Machine Used For Steel Constructure

1. APPLICATION

This machine is mainly used for drilling H-beam, channel steel and box beam, and is widely used in steel fabrication buildings, bridges, three-dimensional garages and other industries. The 7-axis CNC section steel 3D drilling machine adopts seven servo motors to realize drilling positioning in two vertical directions, one horizontal direction and one longitudinal direction and servo feeding of three spindles. There are 3 drilling surfaces, each with 1 drilling spindle, and 1 drilling spindle on each surface is driven by a frequency conversion motor. The drilling spindle is a servo feeding drilling spindle. When the hole diameter of the workpiece is 1, the holes on the three sides of the workpiece can be processed after passing through the machine at one time, with high efficiency and high hole position accuracy.

It is an indispensable machine to ensure quality in the steel fabrication manufacturing industry.2.TECHNICAL DATA

Name Unit Specifications H-beam: Max. height × Max. width (Flange width) mm 650×300 H-beam: Min. height × Min. width (Flange width) mm 150×100 Automatic feed conveyor length mm 12000 Max. workpiece web thickness mm ≤25 Maximum workpiece weight kg 2000 Number of drilling spindles 个 3 Drilling Diameter Range mm φ5-30 Upper unit spindle technical parameters Number of upper spindles KW 11 Spindle rated torque Nm 140 Spindle speed range r/min 0~3000 Axial feed speed mm/min 0~4000 Spindle feed stroke mm 400 Spindle centerline lateral movement range mm 30~600 Left unit spindle technical parameters (reference side) Drilling spindle power KW 11KW Spindle rated torque Nm 140 Spindle speed range r/min 0~3000 Axial feed speed mm/min 0~4000 Spindle feed stroke mm 200 The moving range of the spindle center line up and down mm 20~270 Right unit spindle technical parameters Drilling spindle power KW 11KW Spindle rated torque Nm 140 Spindle speed range r/min 0~3000 Axial feed speed mm/min 0~4000 Spindle feed stroke mm 500 The moving range of the spindle center line up and down mm 20~270 Spindle taper hole BT40

(Pneumatic loosening knife)

Hole spacing error in hole group mm ≤±0.2 Adjacent hole group hole spacing error mm ±0.2 Bit cooling method spray cooling, external cooling Up and down (vertical) stroke of gripping arm mm 100(50-150) Left and right (lateral) stroke of gripper arm mm 150(50-300) Gripper arm movement (forward direction) stroke mm 12000 Rack and pinion drive servo motor power KW 5 Outline dimensions of feeding channel

(L× W × H)

mm 14000×900×1630 Feed channel length mm 8000 total power KW About 50 Dimensions of the production line L×W×H mm Abou 24000×3500×3120 Automatic conversion of CAD drawings into machining programs

FAQ

· Are you a Manufacturer or a Trading company?

Manufacturer + trading company (integration),focusing on CNC machines for 18 years. Integration with Design,Machining and Assembly.

Exporting to Russia,USA,Australia,Vietnam,Brazil,Ethiopia,Tunisia,Bulgaria,India,Indonesia,Jordan,Pakistan,etc

· Do you have stock product ready to delivery?

In order to satisfy with customer for fast delivery, we have certain amount of machines in stock.

· After an order is placed,when to delivery?

General 30 working days. It depends on specific items and item quantities.

Please check with sale manager for exact delivery time.

· What is the Warranty with After-sale Services?

12 months warranty after delivery. Engineers will provide training program for operation and trouble shouting during installation. They visit customers regularly for service. All questions will be answered within 3 hours and 90% problem will be solved within 24 hours.

After the warranty, the professional after-sale service team will provide perfect technical support and help customer solve problems encountered.

· What about the product quality?

Each machine must be carried out quality examination and test when shipping and delivery goods.